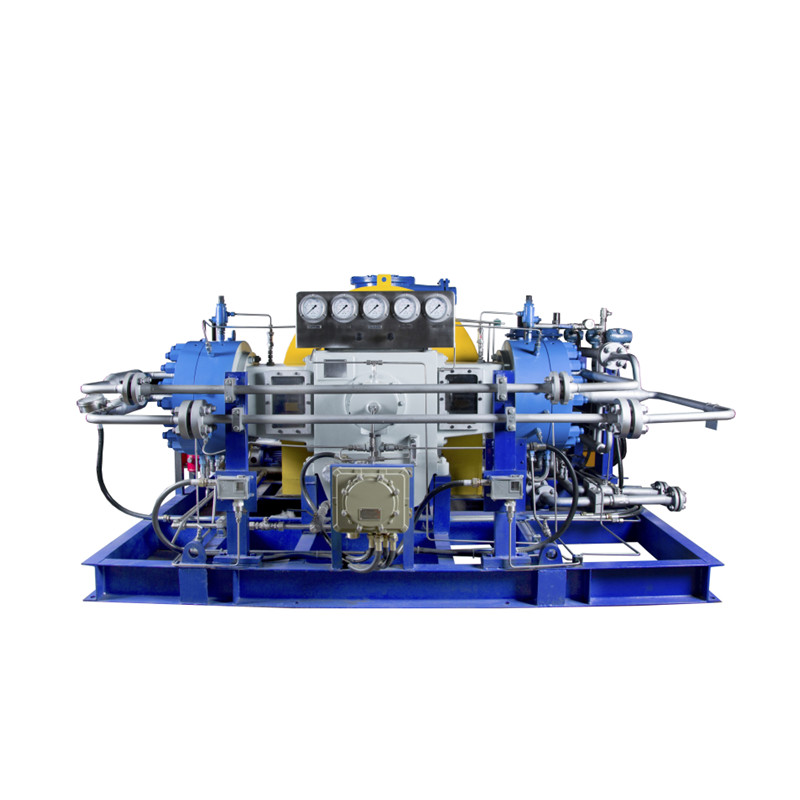

Operasi Stabil Gas Campuran Nitrogen N2 Karbon Dioksida CO2 Diafragma Kompresor Diafragma Kompresor Supplier

Xuzhou Huayan Gas Equipment Co., Ltd.minangka panyedhiya solusi komprèsi gas utama global. Kanthi keahlian akumulasi babagan desain lan manufaktur sajrone pirang-pirang dekade, perusahaan kita duwe kemampuan produksi lengkap sing kalebu tempa profesional, casting, perawatan panas, welding, mesin presisi, uji perakitan, lan proses verifikasi kualitas. Didhukung dening tim teknis khusus saka 120 profesional lan fasilitas manufaktur 90.000 m², kita njaga peralatan uji teknis sing canggih lan metode kontrol kualitas sing ketat kanggo njamin kinerja produk sing unggul.

Bisa ngrancang, manufaktur, lan nginstal peralatan miturut paramèter pelanggan tartamtu, saiki kita entuk kapasitas produksi taunan 500 unit kompresor gas. Kaunggulan teknis kita ngidini pangembangan kompresor kanthi tekanan discharge nganti 100MPa, nyukupi syarat industri sing paling nuntut.

Kanthi jejak global nganti luwih saka 50 negara ing limang bawana, kalebu pasar utama kayata Indonesia, Mesir, Vietnam, Korea Selatan, Thailand, Finlandia, Australia, Republik Ceko, Ukraina, lan Rusia, kita ngirim solusi turnkey lengkap kanggo klien ing saindenging jagad. Komitmen kita kanggo keunggulan operasional njamin saben pelanggan nampa peralatan kinerja dhuwur sing dipasangake karo dhukungan teknis profesional lan layanan responsif.

METER KOTAK

TIM TEKNIS

PENGALAMAN MANUFACTURING

NEGARA EKSPOR

A kompresor diafragmaminangka kompresor pamindhahan positif khusus sing misuwur amarga kemampuan kanggo nangani gas kanthi kemurnian, sensitivitas, utawa bebaya sing luar biasa tanpa kontaminasi utawa bocor. Ora kaya kompresor piston tradisional, nggunakake diafragma sing fleksibel lan hidrolik kanggo ngisolasi gas sing dikompres saka crankcase lan piston sing dilumasi.

Fitur utama:

1,Hermetic Sealing: Diafragma logam utawa elastomer nggawe penghalang anti bocor sing lengkap ing antarane gas lan cairan hidrolik / pelumas. Iki minangka ciri sing nemtokake.

2.Zero Kontaminasi: Njamin gas sing dikompres tetep bebas lenga lan ora terkontaminasi dening pelumas utawa partikel nyandhang saka mekanisme drive. Penting kanggo aplikasi kemurnian dhuwur.

3.Nyegah Bocor: Sakbenere ngilangi emisi buronan, dadi kritis kanggo nangani gas beracun, gampang kobong, mbledhos, utawa mbebayani kanggo lingkungan.

4.Kapabilitas Tekanan Dhuwur: Bisa entuk tekanan discharge sing dhuwur banget (asring nganti 3000 bar / 43.500 psi lan ngluwihi), utamane ing konfigurasi multi-tataran.

5.Penanganan Gas Serbaguna: Cocog kanggo compressing sawetara saka sudhut gas, kalebu Highly reaktif, korosif, Ultra-murni, larang, utawa jinis mbebayani sing bakal ngrusak utawa terkontaminasi dening desain kompresor liyane.

6.Tingkat Aliran Sedheng: Biasane dirancang kanggo tingkat aliran kurang kanggo medium dibandhingake kompresor reciprocating utawa centrifugal gedhe.

Gas sing cocog

Gas sing cocog

1,Pangolahan Petrokimia & Kimia: Kompresi intermediet banget korosif, reaktan beracun (contone, ing produksi PVC karo Cl₂), gas regenerasi katalis, kompresi hidrogen kanggo hydrocrackers/hydrotreater sing kemurnian kritis.

2.Minyak & Gas: Kompresi gas subsea, injeksi gas (pemulihan minyak sing ditingkatake), kompresi hidrogen kanggo kilang.

3.Produksi Semikonduktor: Penting kanggo nyediakake kemurnian ultra-dhuwur (UHP) lan gas khusus sing mbebayani (kayata AsH₃, PH₃, SiH₄) kanggo piranti fabrikasi tanpa kontaminasi.

4.Analitik & Laboratorium: Nyedhiyakake gas pembawa murni, bebas kontaminasi, gas kalibrasi, lan gas sampel kanggo instrumen kaya GC-MS.

5.Aerospace & Testing: Pasokan gas tekanan dhuwur (He, N₂) kanggo nguji komponen roket, sistem tekanan, terowongan angin.

6.Medis & Farmasi: Produksi lan botol gas medis kemurnian dhuwur (O₂, N₂O), udara steril kanggo proses.

7.Industri Nuklir: Nangani coolant helium utawa tutup gas.

8.Energi & Hidrogen: Kompresi hidrogen kanggo sel bahan bakar, stasiun pengisian bahan bakar hidrogen (HRS), lan riset produksi/simpenan hidrogen.

9.Teknologi Lingkungan: Compressing dijupuk CO₂ kanggo sequestration utawa pemanfaatan (CCUS).

| Model | Banyu adhem (L/h) | Aliran (Nm³/h) | Tekanan Inlet (MPa) | Tekanan Outlet (MPa) | Ukuran L × W × H (mm) | Bobot (Kg) | Daya Motor (kW) | |

| 1 | GD-120/4-80 | 3000 | 120 | 0.4 | 8.0 | 3000×1600×1400 | 4000 | 30 |

| 2 | GD-130/0.98-11 | 3000 | 130 | 0.098 | 1.1 | 3000×1800×1600 | 4000 | 30 |

| 3 | GD-150/2-20 | 3000 | 150 | 0.2 | 2.0 | 3000×1800×1600 | 4000 | 37 |

| 4 | GD-100/0.1-5 | 4000 | 100 | 0.01 | 0.5 | 2800×1500×1500 | 3000 | 18.5 |

| 5 | GD-100/5.5-200 | 5000 | 100 | 0.55 | 20 | 3200×2000×1600 | 4500 | 45 |

| 6 | GD-80/0.12-4 | 5000 | 80 | 0.012 | 0.4 | 2800×1600×1500 | 3800 | 15 |

| 7 | GD-60/0.3-6 | 4000 | 60 | 0.03 | 0.6 | 2800×1600×1500 | 4000 | 15 |

| 8 | GD-70/0.1-8 | ,3800 | 70 | 0.01 | 0.8 | 3000×1600×1250 | 5000 | 18.5 |

| 9 | GD-40/0.02-160 | 5000 | 40 | 0.02 | 16 | 2800×1460×1530 | 3000 | 22 |

| 10 | GD-100/0.5-6 | 2000 | 100 | 0.05 | 0.6 | 3000×2000×1560 | 6000 | 18.5 |

| 11 | GD-36/1-150 | 4000 | 36 | 0.1 | 15 | 3000×1500×1500 | 4000 | 45 |

| 12 | GD-35/0.7-300 | 4000 | 35 | 0.07 | 30 | 3000×1600×1500 | 4000 | 22 |

Kita duwe sertifikasi sing diakoni sacara internasional kalebuCElanISOstandar (akreditasi deningIAF), ugaECMpangenalan tundhuk. Sertifikasi iki nduduhake komitmen kita sing ora owah kanggo kualitas, safety, lan tanggung jawab lingkungan:

- Tandha CEnjamin tundhuk karo peraturan safety, kesehatan, lan lingkungan EU, njamin akses pasar gratis ing saindenging Eropa.

- Sertifikasi ISO(didhukung dening akreditasi IAF) validasi ketaatan kita marang sistem manajemen kualitas sing wis ditemtokake sacara global, nambah konsistensi operasional lan kapercayan pelanggan.

- Pangenalan ECMnandheske keselarasan kita karo standar teknis lan kinerja khusus industri.

Yen pasar utawa proyek sampeyan mbutuhake sertifikasi tambahan (contone,API,ASME, utawa persetujuan khusus wilayah), tim teknis lan kepatuhan sing berpengalaman bakal kerja sama karo sampeyan kanggo entuk sertifikasi sing dibutuhake kanthi efisien. Kita ngatur proses kanggo nyukupi syarat peraturan sampeyan, njamin entri pasar sing lancar kanggo peralatan kita.Kanggo dhukungan sertifikasi utawa klarifikasi, hubungi kita kanggo ngrembug solusi khusus.

kita90.000+Meter persegifasilitas produksi modern, staffed dening120+profesional, ngirim solusi engineering selaras karo Kapabilitas Manufaktur tliti. Dilengkapi 20 pusat mesin CNC majeng, kita nangani workpieces nganti1200 mmdiameteripun kanthi akurasi tingkat mikron (0,01 mm). Protokol kontrol kualitas sing ketat kalebu inspeksi lengkap komponen kritis nggunakake CMM (Mesin Ukur Koordinasi) lan tes beban multi-phase dening insinyur sing disertifikasi sawise perakitan. Saben unit ngalami validasi kinerja kanggo tundhuk karo standar ASME/API lan spesifikasi klien, sing didhukung deningSertifikat ISO 9001manajemen kualitas kanggo dilacak, pangiriman dipercaya.

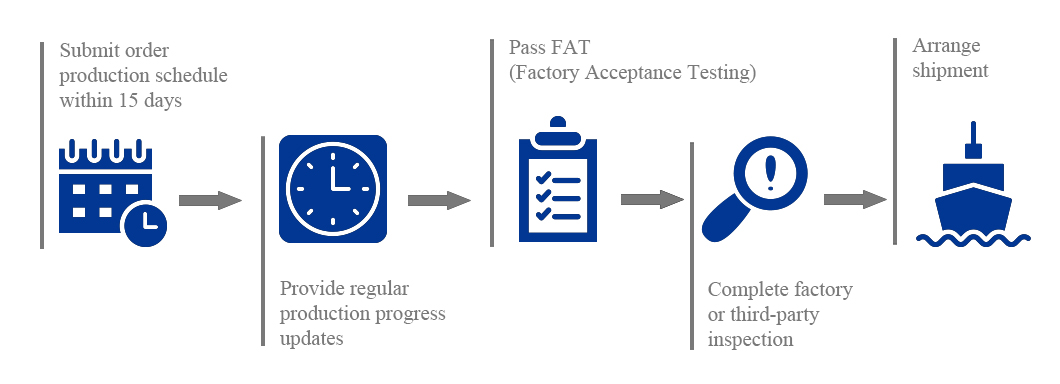

Kita nggunakakebebas fumigasirangka kayu soliddisertifikasi dening ekspor internasional ISOstandar karantina. Dikuatake kanthi internal kanthi baja saluran kanggo dhukungan telung dimensi, njaba dibungkus karo pelindung sudhut logam sing kandel 0.8mm lan diamanake ing sambungan nggunakaketali baja galvanis anti banyu. Desain iki njamin resistance impact, daya tahan komprèsi-bukti, pangayoman Kelembapan, lan Nyegah karat saindhenging transit, njamin barang sampeyan teka kanthi aman.

Perusahaan kita bakal nggawe jadwal pangiriman khusus kanggo proyek sampeyan, didhukung dening solusi logistik terpadutransportasi udara, segara, lan darat.

Kanthi nggunakake jaringan domestik lan kemitraan global China, kita njamin operasi lintas wates sing efisien kanthi pelacakan wektu nyata, dhukungan bea cukai, lan kapabilitas gudang terikat. Fleksibilitas multi-modal njamin pangiriman biaya-efektif lan pas wektune kanggo kabeh jinis kargo.

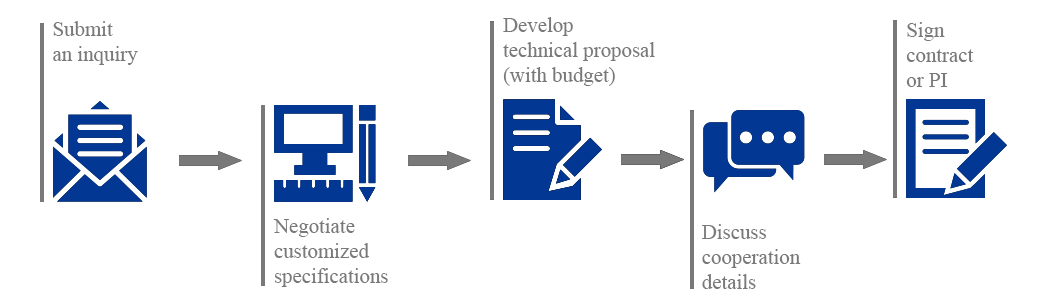

1.Carane njaluk kutipan cepet saka kompresor gas?

1) Laju Alir/Kapasitas : ___ Nm3/jam

2) Tekanan Suction/ Inlet : ____ Bar

3) Tekanan Discharge / Outlet : ____ Bar

4) Sedheng Gas :_____

5) Tegangan lan Frekuensi : ____ V/PH/HZ

2. Suwene wektu pangiriman?

Wektu pangiriman kira-kira 30-90 dina.

3. Apa babagan voltase produk? Apa bisa disesuaikan?

Ya, voltase bisa disesuaikan miturut pitakon sampeyan.

4. Bisa nampa pesenan OEM?

Ya, pesenan OEM banget sambutan.

5. Bakal nyedhiyani sawetara spare parts saka mesin?

ya wis