Tipe Gz Kompresor Oksigen Kemurnian Tinggi Gas Alam Kompresor Diafragma Hidrogen Kompresor LPG Nitrogen

Kompresor gas diafragma minangka kompresor volume saka struktur khusus. Iki minangka cara kompresi tingkat paling dhuwur ing bidang kompresi gas. Cara kompresi iki ora duwe polusi sekunder. Wis pangayoman apik banget kanggo gas teken. Sealing apik, gas sing dikompres ora dicemari dening minyak pelumas lan impurities padhet liyane. Mulane, iku cocok kanggo compressing dhuwur kemurnian, langka larang regane, flammable lan mbledhos, beracun lan mbebayani, korosif, lan gas tekanan dhuwur.

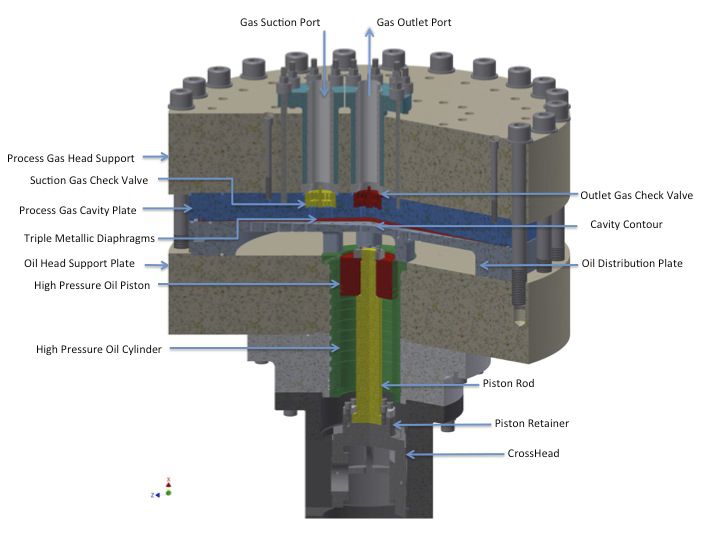

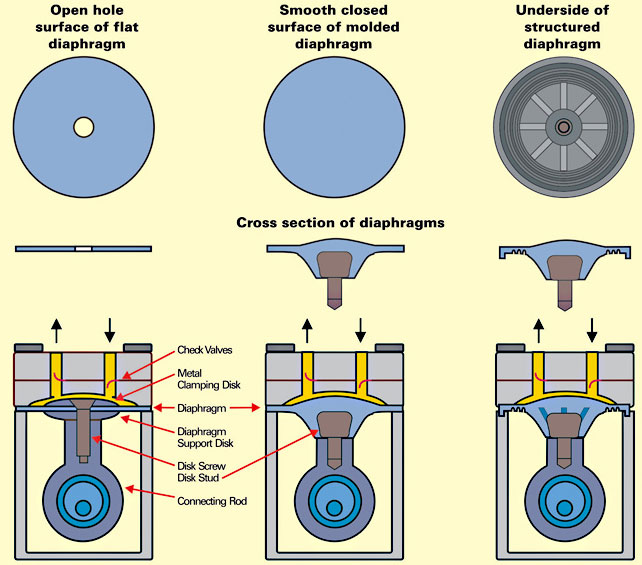

kompresor gas diaphragm iku varian saka kompresor reciprocating klasik karo serep lan piston rings lan rod segel. Kompresi gas dumadi kanthi cara membran fleksibel, tinimbang unsur asupan. Mbalik lan kasebut membran obah mimpin dening rod lan mekanisme crankshaft. Mung membran lan kothak kompresor sing ana hubungane karo gas sing dipompa. Mulane konstruksi iki paling cocok kanggo mompa gas beracun lan mbledhos. Membrane kudu cukup dipercaya kanggo njupuk galur gas sing dipompa. Uga kudu nduweni sifat kimia sing cukup lan tahan suhu sing cukup.

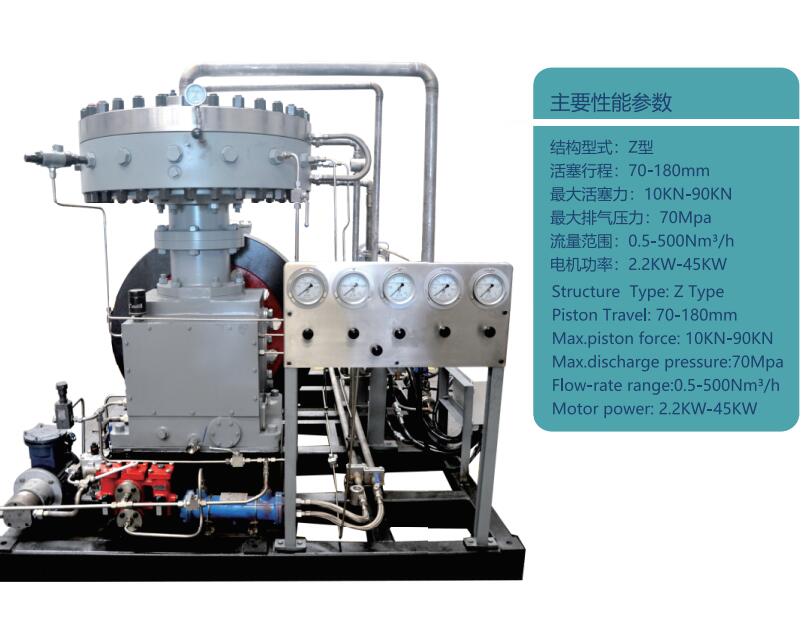

Kompresor diafragma utamane kasusun saka motor, pangkalan, kotak crankshaft, batang penghubung crankshaft, komponen silinder, pipa minyak lan gas, sistem kontrol listrik, lan sawetara aksesoris.

Prinsip Proses sakaKompresor gas diafragma

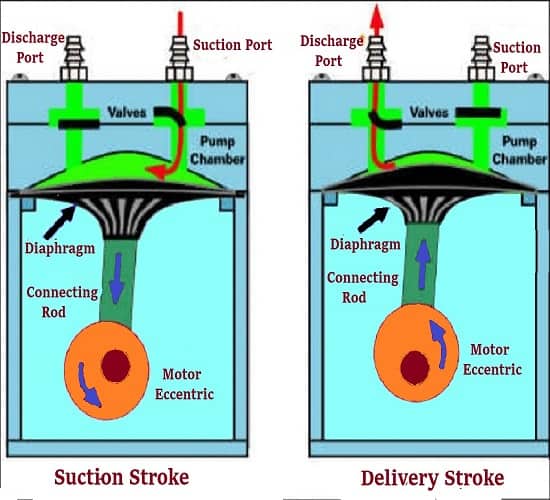

Kompresor diafragma kasusun saka telung potongan diafragma. Diafragma dijepit ing saubengé kanthi sisih lenga hidrolik lan sisih gas proses saka proses kasebut. Diaphragm didorong dening driver hidrolik ing sirah film kanggo entuk kompresi lan transportasi gas. Awak utama kompresor diafragma kasusun saka rong sistem: sistem minyak hidrolik lan sistem kompresi gas, lan membran logam misahake rong sistem kasebut.

Sejatine, struktur kompresor diafragma dipérang dadi rong bagéan: kerangka hidrolik lan kerangka gaya pneumatik. Sajrone proses kompresi, ana rong langkah: stroke nyedhot lan stroke pangiriman.

Keuntungan saka kompresor Diaphragm:

- Kinerja Sealing apik.

- Silinder nduweni kinerja boros panas sing apik.

- Rampung Oil-free, kemurnian gas bisa dijamin luwih saka 99.999%.

- Rasio Kompresi Dhuwur, Tekanan discharge dhuwur nganti 1000bar.

- Urip layanan dawa, luwih saka 20 taun.

Dhaptar referensi kompresor diafragma seri GZ

| Model | Konsumsi banyu adhem (t/h) | Pamindahan (Nm³/h) | Tekanan intake (MPa) | Tekanan gas buang (MPa) | Ukuran L × W × H (mm) | Bobot (t) | Daya Motor (kW) |

| GZ-2/3 | 1.0 | 2.0 | 0.0 | 0.3 | 1200×700×1100 | 0.5 | 2.2 |

| GZ-5/0.5-10 | 0.2 | 5.0 | 0.05 | 1.0 | 1400×740×1240 | 0.65 | 2.2 |

| GZ-5/13-200 | 0.4 | 5.0 | 1.3 | 20 | 1500×760×1200 | 0.75 | 4.0 |

| GZ-15/3-19 | 0.5 | 15 | 0.3 | 1.9 | 1400×740×1330 | 0.75 | 4.0 |

| GZ-30/5-10 | 0.5 | 30 | 0.5 | 1.0 | 1400×740×1330 | 0.7 | 3.0 |

| GZ-50 / 9.5-25 | 0.6 | 50 | 0.95 | 2.5 | 1500×760×1200 | 0.75 | 5.5 |

| GZ-20/5-25 | 0.6 | 20 | 0.5 | 2.5 | 1400×760×1600 | 0.65 | 4.0 |

| GZ-20/5-30 | 1.0 | 20 | 0.5 | 3.0 | 1400×760×1600 | 0.65 | 5.5 |

| GZ-12/0.5-8 | 0.4 | 12 | 0.05 | 0.8 | 1500×760×1200 | 0.75 | 4.0 |

| GZ—5/0.5-8 | 0.2 | 5.0 | 0.05 | 0.8 | 1400×740×1240 | 0.65 | 2.2 |

| GZ-14/39-45 | 0.5 | 14 | 3.9 | 4.5 | 1000×460×1100 | 0.7 | 2.2 |

| GZ-60/30-40 | 2.1 | 60 | 3.0 | 4.0 | 1400×800×1300 | 0.75 | 3.0 |

| GZ-80/59-65 | 0.5 | 80 | 5.9 | 6.5 | 1200×780×1200 | 0.75 | 7.5 |

| GZ-30/7-30 | 1.0 | 30 | 0.7 | 3.0 | 1400×760×1600 | 0.65 | 5.5 |

| GZ-10/0.5-10 | 0.2 | 10 | 0.05 | 1.0 | 1400×800×1150 | 0.5 | 4.0 |

| GZ-5/8 | 0.2 | 5.0 | 0.0 | 0.8 | 1400×800×1150 | 0.5 | 3.0 |

| GZ-15/10-100 | 0.6 | 15 | 1.0 | 10 | 1400×850×1320 | 1.0 | 5.5 |

| GZ-20/8-40 | 1.0 | 20 | 0.8 | 4.0 | 1400×850×1320 | 1.0 | 4.0 |

| GZ-20/32-160 | 1.0 | 20 | 3.2 | 16 | 1400×850×1320 | 1.0 | 5.5 |

| GZ-30/7.5-25 | 1.0 | 30 | 0.75 | 2.5 | 1400×850×1320 | 1.0 | 7.5 |

| GZ-5/0.1-7 | 1.0 | 5.0 | 0.01 | 0.7 | 1200×750×1000 | 0.6 | 2.2 |

| GZ-8/5 | 1.0 | 8.0 | 0.0 | 0.5 | 1750×850×1250 | 1.0 | 3.0 |

| GZ-11/0.36-6 | 0.4 | 11 | 0.036 | 0.6 | 1500×760×1200 | 0.75 | 3.0 |

| GZ-3/0.2 | 1.0 | 3.0 | 0.0 | 0.02 | 1400×800×1300 | 1.0 | 2.2 |

| GZ-80/20-35 | 1.5 | 80 | 2.0 | 3.5 | 1500×800×1300 | 0.9 | 5.5 |

| GZ-15/30-200 | 1.0 | 15 | 3.0 | 20 | 1400×1000×1200 | 0.8 | 4.0 |

| GZ-12/4-35 | 1.0 | 12 | 0.4 | 3.5 | 1500×1000×1500 | 0.8 | 5.5 |

| GZ-10/0.5-7 | 0.4 | 10 | 0.05 | 0.7 | 1500×760×1200 | 0.75 | 3.0 |

| GZ-7/0.1-6 | 1.0 | 7.0 | 0.01 | 0.6 | 1200×900×1200 | 0.8 | 3.0 |

| GZ-20/4-20 | 1.0 | 20 | 0.4 | 2.0 | 1400×850×1320 | 0.75 | 2.2 |

Kepiye carane njaluk kuotasi amarga kompresor sing disesuaikan?

Cathetan: kanggo kompresor gas khusus liyane, kirimake informasi ing ngisor iki menyang pabrik kanggo ngetung biaya produksi barang sampeyan.

1. Laju aliran: _______Nm3/jam

2.Media Gas : ______ Hidrogen utawa Gas Alam utawa Oksigen utawa gas liyane?

3. Tekanan Inlet: ___bar (g)

4. Suhu inlet:_____ºC

5. Tekanan Outlet: ____bar (g)

6. Suhu outlet: ____ºC

7. Lokasi instalasi: _____ njero ruangan utawa ruangan?

8. Suhu sekitar lokasi: ____ºC

9. Sumber daya: _V/ _Hz/ _3Ph?

10.Cara cooling kanggo gas: ______ cooling online utawa banyu cooing?